Companies in Alberta and Saskatchewan have been building thermal oil production schemes for a while now and those companies know the ins and outs of what is required prior to building these facilities or making changes to the current scheme. If you are newer and are thinking about embarking on the task of either building from scratch or committing to the ownership of one of these thermal facilities you may what a little heads up as it concerns a little document that isn’t so little.

What is a MARP you ask? Well within Alberta and Saskatchewan there is an overarching requirement that if a producer wants to build a thermal bitumen scheme (Alberta) or thermal heavy oil recovery scheme (Saskatchewan) it is compulsory to have an approved Directive 042; Measurement, Accounting, and Reporting Plan (MARP) approval in place. Within Alberta, it is required to have this approval prior to a Directive 056 licensing application submission, while within Saskatchewan it is required to have this approval prior to injecting or production of a thermal heavy oil project.

A MARP will require a company to understand the facilities set up, operating procedures, process flows, and accounting / reporting practices. The process of developing a MARP can take multiple months to build and will take multiple stakeholder groups to ensure its contents are accurate and meet Directive 017 requirements. Directive 042 lays out the requirements of the MARP to ensure companies have a head start on the required contents.

Below is an outline of the requirements for a MARP document:

General project outline

- Full company name and Business Associate Identifier (BA ID)

- Project name and number (if existing project)

- Application number

- Company contact(s)

- General project/process description and location

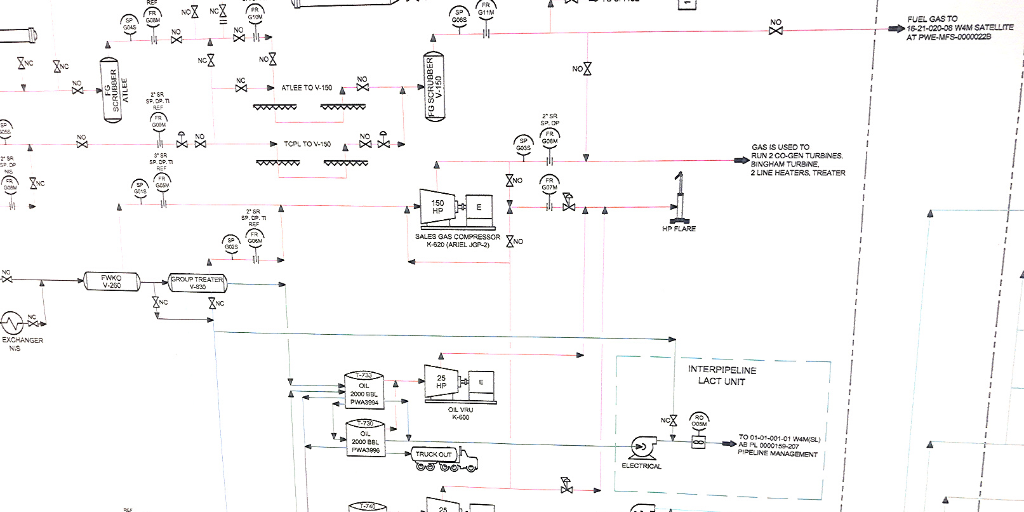

Measurement Schematic

What to Include

- All surface facilities associated with the project, including surface locations, Petrinex facility subtypes (if applicable), facility license numbers (if applicable), process equipment such as:

- Crude oil treating and upgrading,

- Proration testing

- Water treatment

- Steam generation

- Cogeneration

- Waste handling

- Disposal

- A list of all wells associated with the project, indicating how each well will tie into the surface facilities; include and identify crude oil wells, steam/solvent/ gas/water injection and disposal wells, water source wells, and observation wells.

- All applicable receipt points, whether by truck or pipeline; indicate what fluids will be received (e.g. gas, condensate, etc.), the source of the fluids if known (e.g. reporting facility code.)

- All applicable disposition points, whether by truck or pipeline; indicate what fluids will be disposed (e.g. water) and the destination of the fluids (e.g. reporting facility ID.)

- All applicable flow lines, fuel lines, flare lines, recycle lines, skim lines, gas-lift lines, solvent injection lines, and utility lines.

- All applicable crude oil, emulsion, condensate, and water tanks/storage ponds/vessels, with the dimensions and capacity of each.

- All applicable measurement devices (e.g. meters, gauges, product analyzers), measurement points, and sample points.

- Label and indicate the type of measurement device(s)

- Provide a table showing maximum uncertainty of measurement devices.

- If electronic flow measurement (EFM) is used, indicate where measurement devices are configured with EFM.

- Boundaries of applicable production facilities, such as batteries and injection facilities, that report to Petrinex, with the appropriate facility subtype codes.

Current or proposed operating procedures:

- Calibration and Proving – For each measurement device used for accounting and Saskatchewan Ministry of Energy and Resources (MER) reporting purposes, outline the frequency and method of calibration, checking, or proving.

- Gauging – Outline the method of gauging tanks/storage ponds/vessels and the frequency of calibrating applicable gauging devices.

- Trucking – Outline the method(s) of measuring, sampling, and recording production moved by truck to or from the facilities associated with the scheme.

- Sediments and Water (S&W) Procedures – Outline the frequency and method of determining the water cut of proration test production.

- Valid Test Criteria – Provide the criteria for accepting or rejecting proration tests.

- Load Fluid Recovery – Outline the method used to determine well production rates during load fluid recovery.

- Common Flow Lines – Outline the proration test procedure and purge time for wells on common flow lines.

- Field Headers – Outline the proration test procedure and purge time for wells producing to field headers. Provide test line capacity and test and group operating line pressures.

- Casing Head Gas – List wells using casing head gas and/or produced gas for fuel.

- Gas Lift – List the wells using gas lift.

- Primary and Secondary Measurement – Provide detail on how primary and secondary measurement will be performed at the facility.

Accounting Calculations and Reporting:

- Estimated Production Worksheet – For proration batteries that make up the thermal heavy oil project, provide a sample worksheet for determining the estimated crude oil, gas, and water production for each well.

- Accounting Formulas – For each production facility reporting to Petrinex, provide the calculations and cite the applicable measurement points used to determine the following:

- Bitumen/Crude oil production, disposition(s), and inventories.

- Gas production, disposition(s), and receipts.

- Water production, disposition(s), receipts, and inventories

- Water source production, disposition, receipts, and inventories; include copies of the most recent water analysis for all water wells and sources.

- Condensate, solvent, and non-condensable gases receipts, injection, disposition, and inventories.

- Total fuel, flare, and vented gas.

Outline the methods used to:

- Calculate/estimate the volume of water vapor in the metered gas streams and procedures used. To adjust metered gas volumes for gas streams operating greater than 100 degrees Celsius (corrected to 101.325 kilopascals absolute.)

- Determine shrinkage when blending hydrocarbon liquids with densities differing more than 40.0 kilograms per cubic meter.

- Determine shrinkage when condensate (diluent) is flashed through heavy crude oil treating and other process equipment.

- Estimate unmetered flare, fuel, vented, and other gas streams; include sample calculations showing all particulars.

- Estimate gas in solution with oil dumped to stock tanks and with crude oil at proration test conditions.

- Determine recovery of injected solvent and non-condensable gases distinct from heavy crude oil and solution gas production.

Other:

- Describe any other estimate, correction, or adjustment procedures used to calculate volumes.

As evident by the above requirements it is a daunting task to not only build one of these facilities but also meet the requirements to get it approved and have the patience to ultimately hurry up and wait while the AER or MER review. The reassuring part of this is that many companies have undertaken this task and succeeded. If you are one of these companies which has more things to do than figure this all out there are specialized companies that can help and guide your company through creating and submitting a MARP to the appropriate regulatory board.

About the Author

Richard Boscher is a Measurement Specialist and Journeyman Instrument Technician at Intricate; a Canadian energy services provider. Richard has been working in Industry for 24 years both as a service provider and as an employee for major producers as a Measurement Coordinator/Specialist.

Sources: AER Directive 042